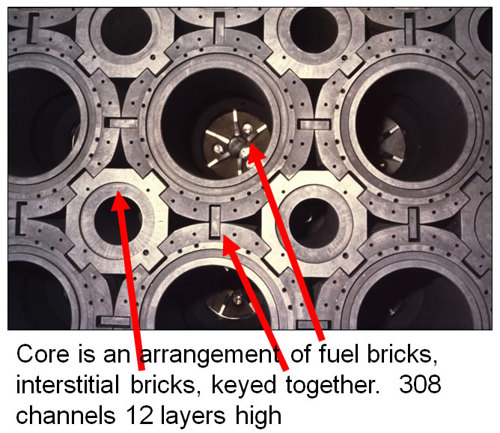

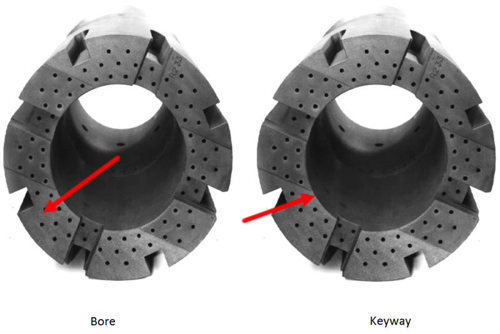

The UK has a long history of using graphite as a moderator from the early Magnox reactors to the Advanced Gas-cooled Reactors (AGRs). The moderator slows down the speed of neutrons produced during nuclear fission and helps to sustain the chain reaction so that the heat can be used for electricity production. In both of these designs, the core is constructed from thousands of interlocking graphite bricks which also form a large number of important channels. These channels contain the nuclear fuel, the reactor control rods and allow the passage of carbon dioxide coolant gas to remove heat from the reactor fuel and core.

The main issue associated with graphite bricks is graphite core ageing (weight-loss and cracking).

The Office for Nuclear Regulation's mission is to protect society by securing safe nuclear operations. ONR would not allow the continued operation of any reactor unless it was safe to do so.

Expertise

The UK fleet of AGRs are now the only power producing nuclear reactors in the world that have a graphite-moderated, carbon-dioxide cooled core. Therefore, the technical community supporting the AGRs is small in relation to that for water moderated reactors and there is a lack of comparable experience outside of the UK.

For several years, ONR has focused on creating and developing a number of independent sources of expert advisors that can conduct research to develop independent models and provide advice which is independent of the licensee.

A graphite technical advisory committee was formed in 2004, consisting of senior academics and other internationally recognised experts in nuclear graphite technology. This continues to provide authoritative advice to ONR and enables us to provide appropriate, authoritative challenge to the licensee's own analysis.

Based on the present challenges facing the AGR graphite cores, ONR inspectors also identified areas where independent research on nuclear graphite would provide valuable contribution to support the judgements made by ONR on the graphite core safety cases. ONR currently funds several graphite-related research contracts which contribute to our robust regulatory decision making process.

The evolving graphite safety cases involve development of complex graphite material models, component stress analysis, prediction of component degradation, whole core modelling, statistical assessment of core state and graphite experimental work. In addition, an independent review of some other aspects of the graphite safety cases submitted by the licensee, EDF Energy Nuclear Generation Ltd (EDF Energy), is also required. ONR inspectors have organised the research projects to align with the aforementioned requirements.

We use a variety of sources including senior academics and other internationally recognised experts in nuclear graphite technology to utilise the independent capabilities of each organisation. The University of Manchester, through the Nuclear Graphite Research Group (NGRG), has extensive experience in nuclear graphite modelling and simulation and the development of material models. The Health and Safety Laboratory has extensive experience in statistical modelling and the University of Birmingham has extensive experience in materials testing.

Although the different projects are independent from each other, in reality those projects are linked together as they complement each other to provide a source of knowledge and advice to support our work across each of the areas important to the behaviour of nuclear graphite. Our inspectors have created an environment of collaboration which enables flow of information and knowledge transfer between the different projects.